NOTEBOOK

News and updates about the first zero-energy shared-ownership rental cabin.

When it comes to materials choices for your home, flooring is one of the biggest design decisions you will make. It’s a major visual presence in every room, and, unless you jump around a lot, you will be in almost constant physical contact with it.

It seems that a dual-flush toilet would be the right choice for an eco-friendly house, but this single-flush Toto toilet changed my mind.

Zero-energy houses, Passive Houses, and other air-tight and efficient modern homes need makeup air for their kitchen exhaust fan vents. We chose the silent S&P inline duct fans. Here’s how our system works.

Alex, Leon, and I were lucky enough to spend the month of June at Artemisia, en route to Madison, Wisconsin, where we are moving. It was great to be able to settle in for a while and enjoy the spectacular Methow Valley and our zero-energy cabin.

The best way to protect your home from severe weather is to pay attention to where you site it. If that's not possible, you have to think carefully abut your materials and building techniques.

This is one of my favorite times of year in the Methow Valley. The summer rush is over, and the ski season isn't quite in full swing. Alex, Leon, and I had the good fortune to be able to spend a long four-day weekend at the house, and it was wonderfully relaxing. We've started renting the house on Airbnb over the last few months, and it has been great to see how well our guests have taken care of it.

The building inspector came by last week to do the final inspection of our cabin. He just found a few things that we were able to complete immediately (add house number, install a missing piece of drywall in the pantry) and passed us.

We've been busy putting the finishing touches on our zero-energy cabin, and we're really happy with how it's turned out. Compared to the "big show" of the walls and interior framing going up, this final phase of finish work seemed like it went very slowly.

After getting bumped from our first tiler's schedule, Sy came up from Chelan to install our backsplash and shower pan. We ran into some issues with the porcelain tile we originally chose for the kitchen. Our electrical outlets were placed too close to the top of the backsplash, and the tiles Sy tried to cut kept breaking.

Our cabin is nearly ready for use! Alex, my mom, Leon, and I headed out to Winthrop for a three-day weekend to celebrate my birthday and work on what seems to be a never-ending punch list of little tasks that need to be completed before we start enjoying the house. I spent much of the last couple trips sealing and installing the custom rusted-steel trim for the baseboards and doors. It came out looking really cool, I think, and adds a nice rustic touch to the look of the place. Thanks to our neighbor Michael Guilfoil for the idea.

The New Year has come and gone, and Artemisia is still under construction. But we're getting closer to reaching the finish line and starting to enjoy our zero-energy shared home.

The house is feeling much brighter and more spacious on the inside now that it has been painted. Our drywall installer sprayed on a very light orange-peel texture and then two coats of zero-VOC paint. We chose to pay a slight premium for this premium paint to avoid the odors and off-gassing of traditional paints.

The drywallers have been working hard, and all the panels are now hung, taped, and mudded. Since we last visited the site, they have come back and sprayed zero-VOC primer and a light orange-peel texture. The zero-VOC paint should be sprayed by Monday.

People often write to me via our blog for our first zero-energy house and ask what we would have done differently with the benefit of hindsight. In all, we're extremely pleased with our Seattle home, located in the Ballard neighborhood. At the time of construction, it was the first net-zero-energy house in the Seattle city limits, and it's been just perfect for our growing family. While it's hard to come up with things we'd like to change that aren't related to wishing we had a bigger budget to buy more expensive finishes and such, there was one area we wish we'd given more thought to: acoustics.

The house is really coming along. Here's what's happened lately:

- Finished air sealing and achieved .50 ACH at 50 pascals with blower door test

- Installed Roxul Safe-N'Sound acoustical mineral insulation in all interior walls and most floor joist bays

- Completed exterior siding

Last weekend was a reckoning of sorts. We've been focusing on making the house as air tight as possible ever since the framing stage. The structural insulated panel (SIPs) construction goes a long way, but ensuring a tight envelope requires attention to small details, like filling or sealing off all cracks and gaps around windows and doors and between panels. The foam and caulk guns have been our constant companions of late.

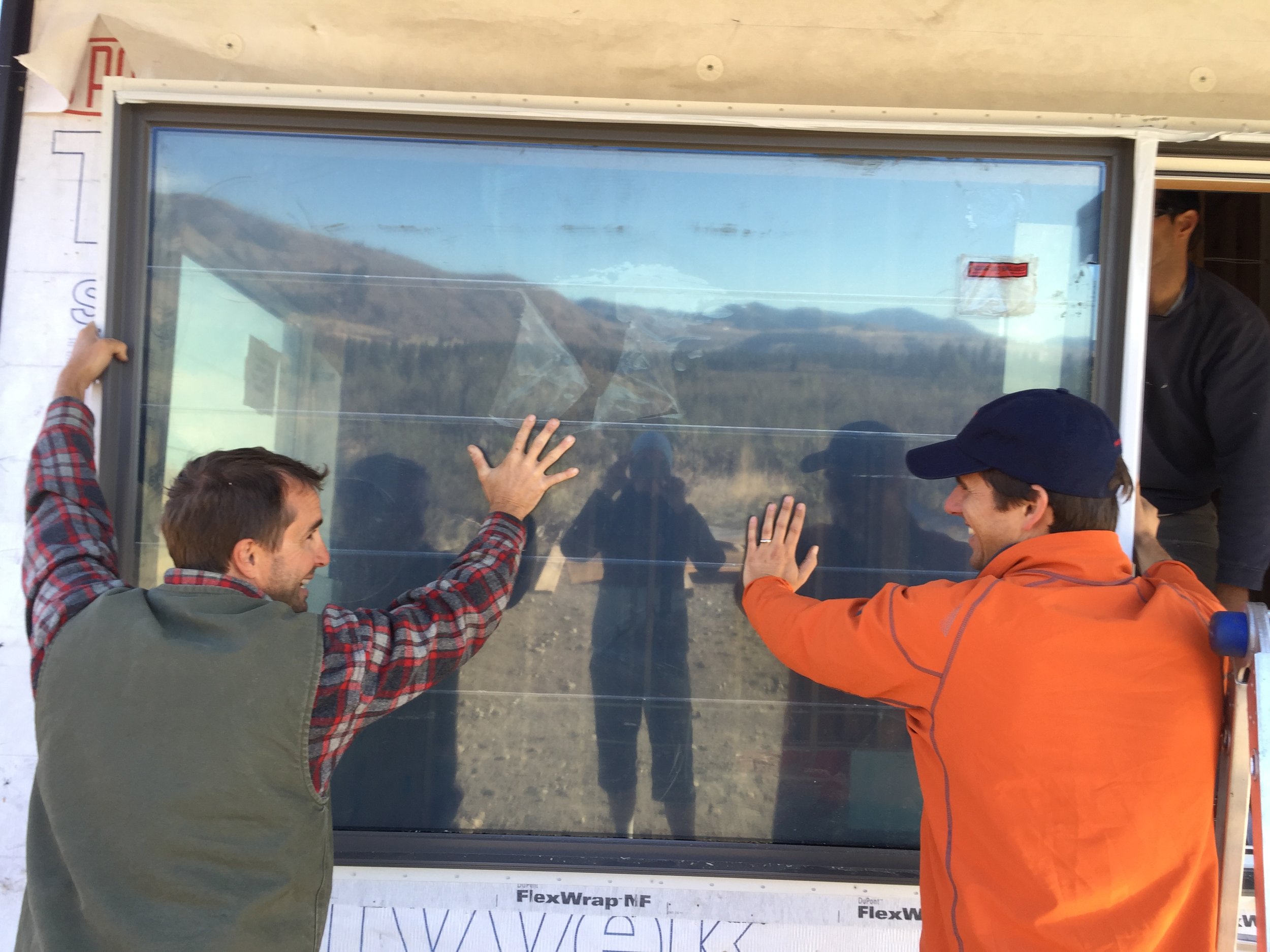

Snow is already falling in the passes, and winter is coming on fast. Luckily, we are now “dried in,” meaning the exterior of the house is complete and waterproof. Well, almost. We still have one small section of siding to complete, around the large south window that broke in shipment and had to be replaced. We are hoping to have that complete by next week.

With this snazzy new standing-seam metal roof, the house is starting to look pretty put together, from the outside at least. Our 16 to 21 solar panels (still deciding on the number) will clip onto the raised metal seams. We've designed the south-facing roof to be at the ideal pitch to catch the most sun.

Despite some setbacks, progress continued last week through the weekend. Our framer, Gary Giltner, of Giltner Construction, came back to make a few adjustments to the interior framing and install siding, windows, and doors (not all of which ended up making it to the jobsite on time).

Alex and I haven't been able to travel to Winthrop for the last two weeks because Alex is nine months pregnant with our first child (due date August 30!), and we have to stay close to the hospital. However, a lot has been going on with the cabin, and Dave and Lisa have been working hard on the jobsite. There has also been a fair bit of drama in the materials delivery department.

We had seen it as a rendering, and we had seen photos of the house taking shape, but that was no comparison to seeing the completely framed home in person. When Alex and I drove into Winthrop, we craned our necks to see the tip of the roof (and were happy to see that the house wasn't visible from the main road). But driving up West Chewuch, we finally got to see the structure we had been working so hard to plan. And we were thrilled.

It's only been two days, but our framing contractor has already set all the panels of the first floor. One of the reasons we chose to build with SIPs (structural insulated panels) is that they can go up very quickly, while maintaining excellent air-tightness and insulative qualities.

It's been a long journey, but after many rounds of design revisions, many conversations with general contractors, and much excitement, we've finally broken ground on our net-zero-energy cabin in Winthrop, WA.

How do people interested in building a zero-energy home get started? The process usually begins with a lot of online research. Over the course of building two net-zero homes, we've read a lot, learned a ton, and gathered a lot of resources. Below are some of the top websites and online resources for homeowners and building professionals looking to expand their knowledge of zero-energy building. Enjoy!

When Alex and I built our net-zero-energy house in Seattle, we didn't have to worry much about snow. Seattle gets just under 6 inches of snow per winter. The Methow Valley couldn't be more different. Unlike mild Seattle, it is a place of extremes: extremely hot in the winter, very cold in the winter, and lots of snow—56 inches average per year.

Our little group ventured over to the Methow Valley last weekend for the first homeowner's association meeting of Methow Valley View. Dave and Lisa had visited our land several times during the last few months, but Alex and I hadn't had the chance to return since we first saw the lot in the winter.

Alex and I have been going to the Methow Valley for years. We've enjoyed skiing in the winter with family, camping with friends in the summer, running the Sunflower Relay marathon, and sampling tasty baked goods from the Mazama Country Store. Like so many people, we were attracted to the area's stunning beauty and ample opportunities for outdoor recreation.

As part of our Artemisia Lab program, we’ve been testing the High Sierra shower head. Invented in 2006 by David Malcom, the patented design is inspired by agricultural irrigation nozzles. The result is a high-efficiency, 1.5 gallon-per-minute shower head that isn’t just an incremental improvement over the crowded field of competitors but is in a league by itself because it relies on a totally different design. This compact, plumbing fixture, which is shaped kind of like a D-cell battery, could go head to head with any shower head, even higher-flow ones, and win.