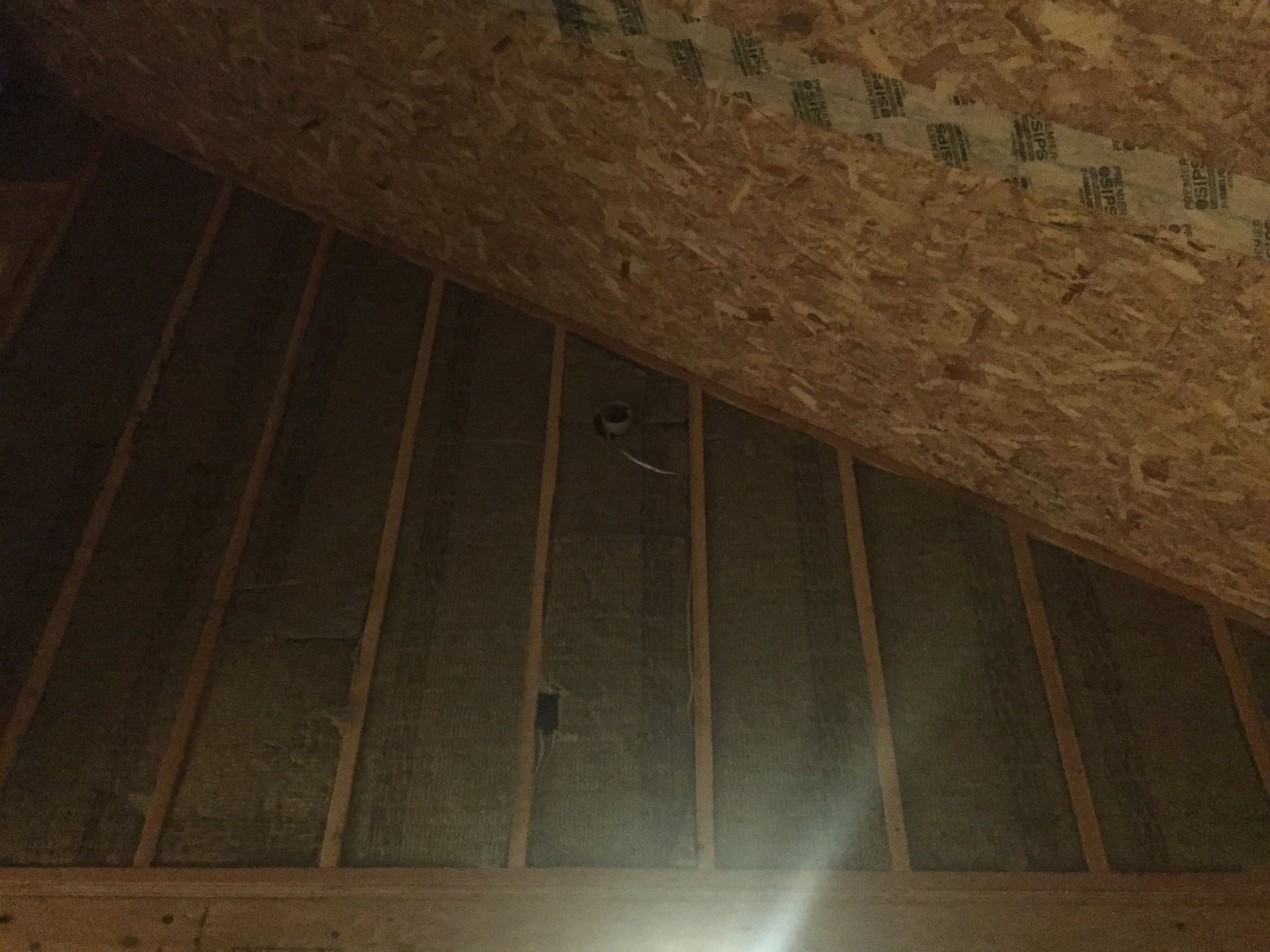

The gray material between the studs is Roxul Safe'N'Sound acoustic insulation, which also adds fire-proofing qualities to the wall.

People often write to me via our blog for our first zero-energy house and ask what we would have done differently with the benefit of hindsight. In all, we're extremely pleased with our Seattle home, located in the Ballard neighborhood. At the time of construction, it was the first net-zero-energy house in the Seattle city limits, and it's been just perfect for our growing family.

While it's hard to come up with things we'd like to change that aren't related to wishing we had a bigger budget to buy more expensive finishes and such, there was one area we wish we'd given more thought to: acoustics.

Much like Artemisia, the Ballard Zero-Energy House has stained concrete floors and high, vaulted ceilings. It can echoey, especially when we have parties. We've identified some acoustical panels we'd like to install . . . someday.

We also had an issue with vibration from the outdoor heat pump resonating on the north wall of the house. We solved that by replacing the rigid copper pipe to the heat pump with loops of flexible hose.

Finally, there isn't as much sound insulation between the floors and between the rooms as we would have liked. We did add some fiberglass batt to deaden the sound, but looking back, we wish we'd done a little more.

With Artemisia, we have the chance to preemptively solve some of these problems.

The heat pumps are on their own concrete piers, physically separate from the house, so we are hoping vibration won't be an issue. We don't have a plan for any echoing in the large interior spaces, but we could add sound deadening panels if we find we need them.

The last issue, sound traveling between the rooms, we think we've solved, or at least improved upon our last attempt. Dave and I spent the last two weekends installing, among other things, Roxul Safe'N'Sound insulation in all the floor joist bays. This product is made from a combination of stone and recycled slag, a byproduct of steel production that would otherwise go to landfill.

The idea is that the Roxul will reduce sound transmission between rooms and floors. We're also installing a product called resilient channel in the first-floor ceilings under higher-traffic loft areas. This steel extrusion allows the drywall to "float" a quarter inch below the joists, so there is no direct path for footsteps above to resonate through the floor.

One last technique we want to try is to use soundproofing goop, which comes in a caulk tube. We're planning on applying this to plywood panels we are installing as an accent down the hallway wall by the stairs and on the wall of the mechanical room facing the great room.

We're hoping that all these approaches together will result in a quiet space, with good sound isolation. This will be important if we ever decide to rent out half of the house while using the other.